Welcome to the DBL Engineering website! In this post, I’ll introduce myself and describe my background.

My name is LeRoy Mietzner, and I’m a degreed Mechanical Engineer and registered Professional Engineer in the State of Washington. After graduating from the University of Washington, I worked for many years designing lifting equipment for a major lift equipment manufacturer in the Seattle area. After leaving that position, I became involved with machinery design for a major consulting engineering firm, working on large lock and dam projects, such as the New Orleans Hurricane Barrier, the Panama Canal Third Set of Locks, and other, similar, projects.

During my time designing lifting equipment, primarily Mobile Elevating Work Platforms (MEWPs), I became mostly involved with structural analysis and stability of boom-supported lifts. One of the characteristics of boom-supported machines is that their mass must be very large, relative to the payload, in order to provide access to work places both far from the base and high up in the air. Why can’t these massive machines be used to lift larger loads, that they are certainly capable of, over a more limited range of motion, I wondered?

Until now, the answer was because there were very few ways to limit the operating range of the machine, other than by allowing the mechanical and hydraulic design limits set the range. This meant keeping payload to a minimum, in order to keep the mass of the machine low enough that it can be transported on a truck or trailer.

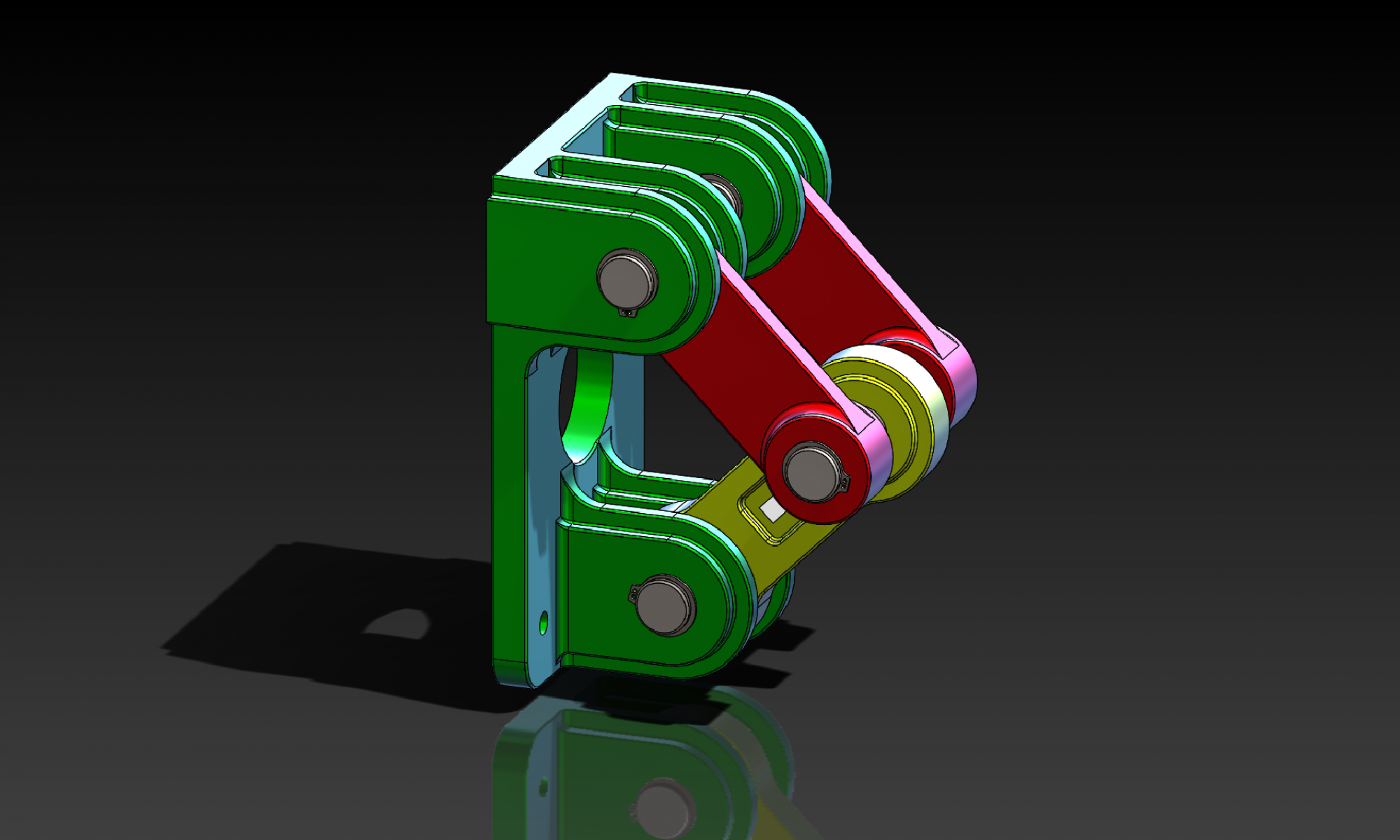

In future postings, I’ll be describing how it is now possible to allow a machine to lift more payload, while effectively limiting its range of motion in order to keep the machine from tipping over, using my (Patent Pending) Boom-Safe Anti-Tip System technology.

Stay tuned!